Thermoplastic Hoses for Hydraulic, Industrial & Ultra High Pressure Applications

Transfer Oil designs and manufactures a comprehensive range of reinforced thermoplastic hoses, fittings, and accessories for fluid and gas transfer in demanding applications. Backed by decades of expertise, full in-house production, stringent quality control and testing, our products are built to deliver reliability, durability, and safety – even under the toughest conditions.

Explore our product families belowOur Product Range

TO Hydraulic Range

Thermoplastic hoses and fittings developed for sectors such as construction, agriculture, and on and offshore equipment, covering a broad range of applications such as steering systems, aerial platforms (truck-mounted and off-highway), rescue tools, cranes, forklifts, servo-control lines, waste compactor vehicles and mining machinery.

Learn more

TO Industrial Range

Thermoplastic hoses and fittings developed for industries such as automation, oil & gas, and chemicals, covering a broad range of applications including water jetting, air cylinder filling, sewer cleaning, hydrogen and CNG refueling (CSA-approved manufacturer and assembler), airless painting, beverage dispensing, and greenhouse spraying.

Learn more.jpg)

Helix® Range

Multispiral thermoplastic hoses and fittings from 700 bar/10,000 psi to 3.800 bar/55,000 psi. These products are designed for applications where extreme pressures are a must, and are ideal for water blasting, heat exchanger cleaning, surface preparation, paint removal, water cutting, hydro-demolition bolt tensioning and pressure test equipment.

Learn moreHydraulic Applications

TO Hydraulic Range

Thermoplastic Hoses and Fittings for Fluid Power Transmission

Consistent hydraulic expertise

Since its founding in the late 1970s, Transfer Oil has specialized in the design and manufacturing of thermoplastic hoses for hydraulic applications. Often considered minor components, hoses are in fact critical for fluid power transmission, ensuring machine efficiency, safety, and long-term performance.

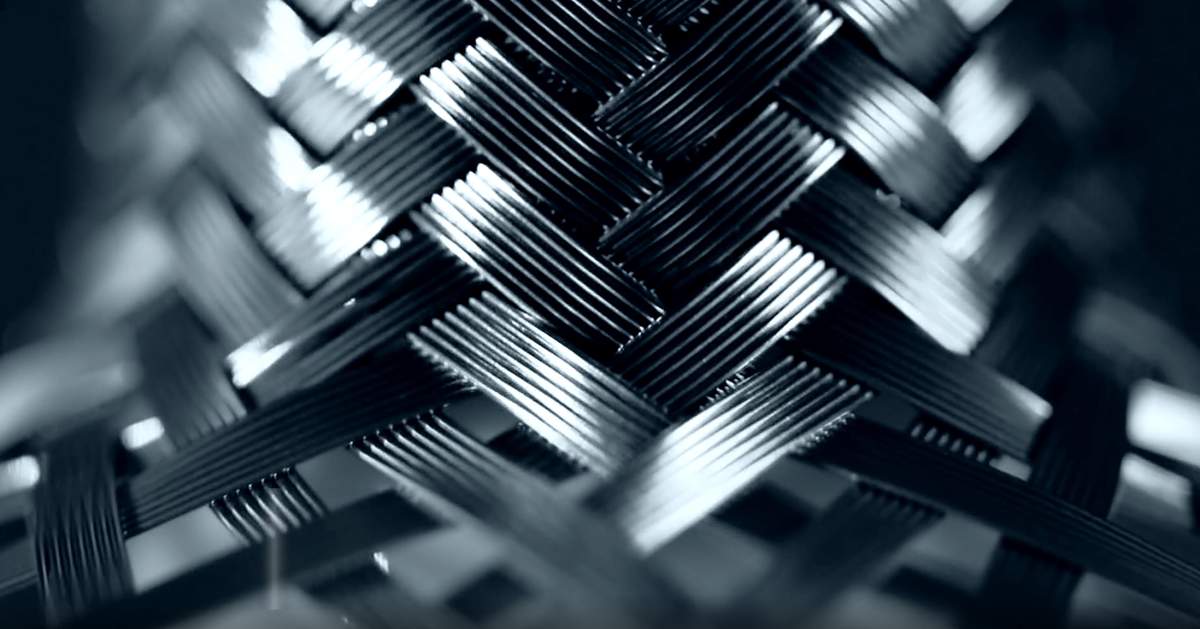

Reinforcement solutions for every pressure range

Our Hydraulic hoses feature different types of reinforcement such as textile braid, steel braid or hybrid combinations of steel braids and synthetic fibers – each tailored to meet specific pressure and flexibility requirements of modern hydraulic systems.

Designed for demanding hydraulic systems

Transfer Oil Hydraulic hoses are designed for applications requiring high durability, minimal volumetric expansion, and robustness under continuous heavy-duty use, like lifting equipment (mobile cranes, aerial platforms, telehandlers, forklifts and hose reeling), hydraulic wrenches, rescue tools, steering systems, waste compactor vehicles and mining machinery.

Main applications

Product Specifications

Sizes

from 5/64” to 1”

Maximum working pressure

up to 800 bar (11,500 psi)

Options

twin-line, multiline (up to 6 lines)

Industrial Thermoplastic Hoses

TO Industrial Range

Hoses and Fittings for Fluid and Gas Conveying Applications

A wide range of industrial applications

Thermoplastic hoses and fittings developed for a broad range of applications including water jetting, air cylinder filling, sewer cleaning, hydrogen and CNG refueling (CSA-approved manufacturer and assembler), airless painting, beverage dispensing, and greenhouse spraying.

Reinforcement configurations

With reinforcement options including textile braid, steel braid or hybrid combinations, our hoses are optimized for pressure resistance, reduced bend radii, and mechanical stress requirements, making them the ideal choice for modern industrial equipment.

The Ecology Line

One of the highlights of our Industrial range is the Ecology line, developed specifically for sewer jetting. These hoses are compact, lightweight, and highly abrasion-resistant thanks to the tough polyurethane cover, that provides protection against mechanical wear, aggressive environments, and microbiological attack – ensuring a longer hose life in wet, harsh working conditions.

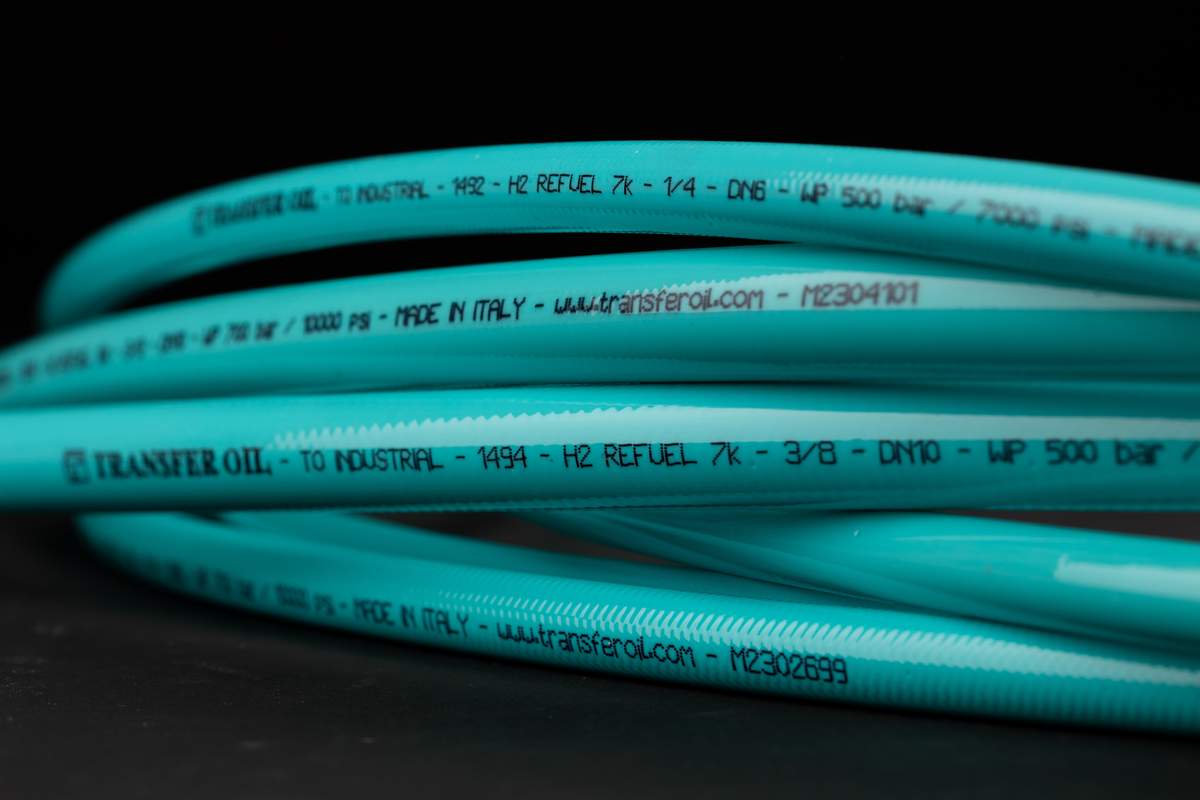

Supporting low-carbon mobility with CNG and Hydrogen hoses

Our CNG hoses operate at 350 bar (5,000 psi) and feature hybrid aramid-textile reinforcement, a low-permeability inner core and electrically conductive properties to prevent static discharge. For hydrogen refueling applications, our H2 hoses meet ISO 19880-5 standards and are built with steel and aramid reinforcements to withstand extreme pressure up to 1040 bar (15,000 psi).

Main applications

Product Specifications

Sizes:

from 5/32” to 1+1/2”

Maximum working pressure:

up to 1040 bar (15,000 psi)

Ultra High Pressure

Helix® Range

Hoses and accessories for Extreme Pressure Applications

Helix® – Engineered for extreme pressure

Transfer Oil has long been a pioneer in the production of high-pressure hoses. In 2015, we introduced Helix®, our complete line of multi-spiral thermoplastic hoses, inserts, and ferrules engineered for Ultra High Pressure (UHP) applications up to 3,800 bar (55,000 psi). The Helix® trademark is inspired by the spiral shape formed by the wire reinforcement around the hose.

Designed for the toughest applications

Developed in accordance with the WJTA color coding scheme, Helix® hoses are engineered for critical applications such as water blasting, heat exchanger cleaning, surface preparation, paint removal, water cutting, hydro-demolition, bolt tensioning and pressure test equipment.

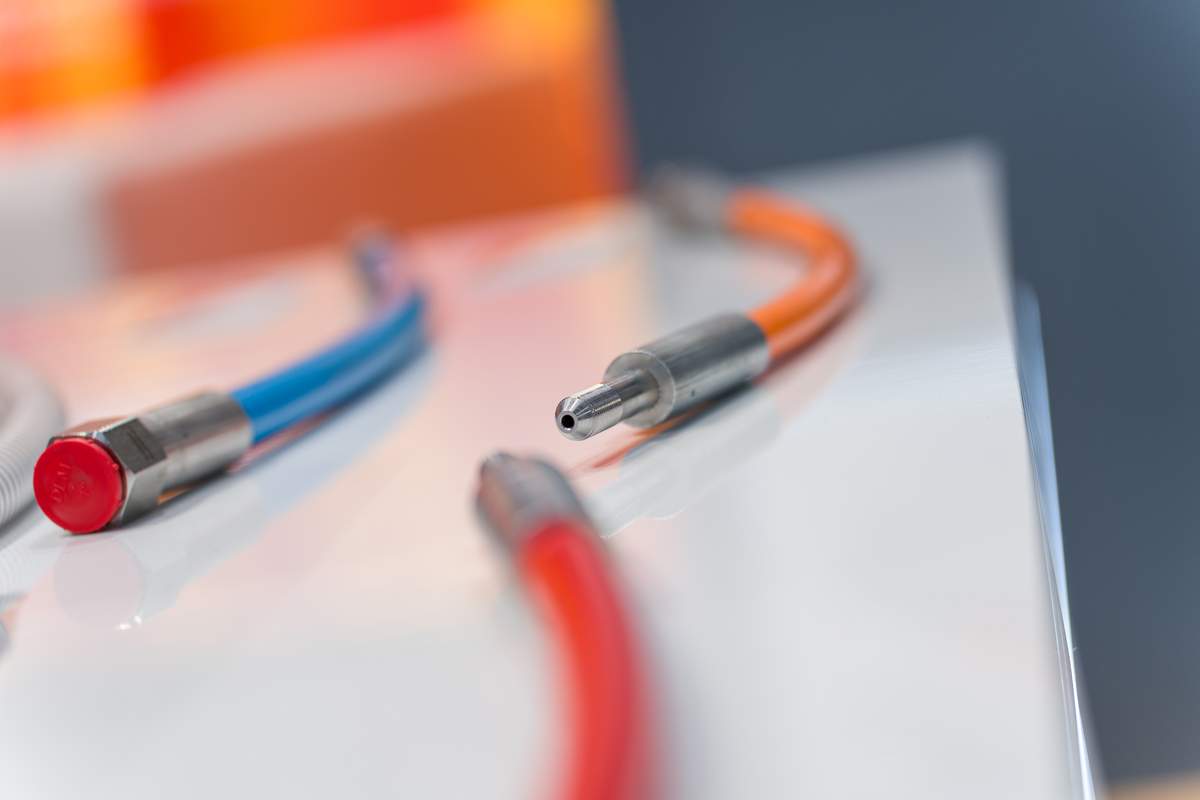

Factory-made assemblies for maximum safety

All Helix® assemblies are exclusively factory-made to ensure full compatibility and safety. Each hose undergoes rigorous in-process quality checks – from raw materials selection to final assembly – and is 100% pressure tested before shipment, ensuring compliance with the most demanding performance and safety standards.

Wide range of accessories

The range is complemented by a full set of safety-focused accessories, including protection jackets, hose arrestors, stainless steel catch rings, and bend restrictors – each contributing to making the hose assembly durable and safe under extreme conditions.

Main applications

Product Specifications

Size Range:

1/8” to 1”

Working Pressure:

up to 3,800 bar (55,000 psi)